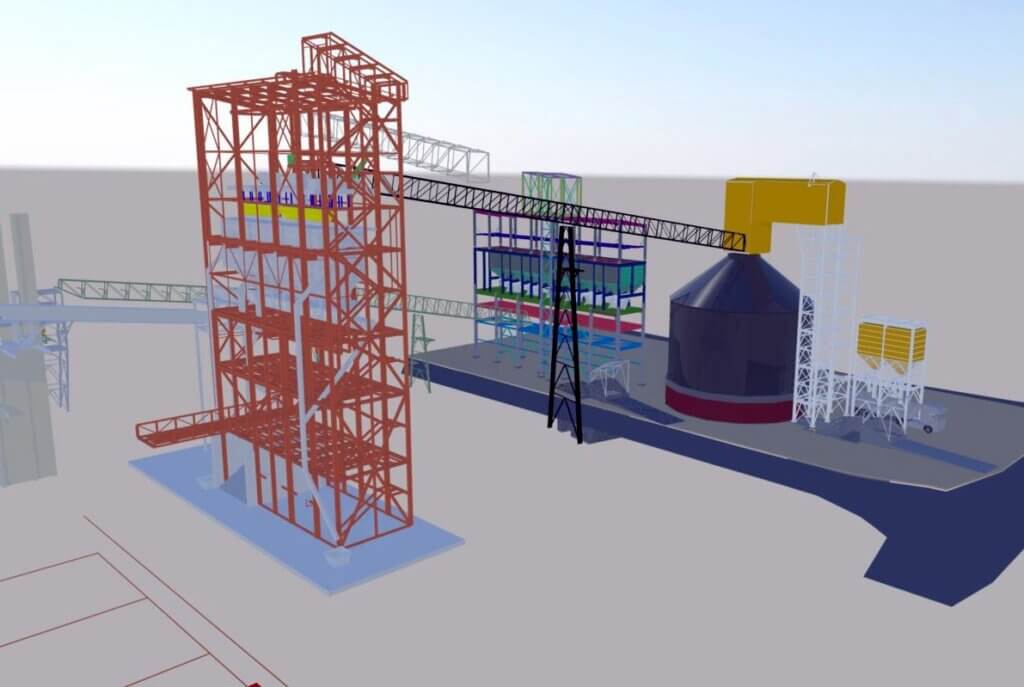

An important step towards accelerating progress towards carbon neutrality in Spain which will reduce CO2 emissions by 4.8 million tonnes within the next five years. At the heart of the plan is a 2.3 million tonne green hydrogen DRI unit, complemented by a 1.1 million tonne hybrid EAF.

This begins the transition of the Gijón plant from the blast furnace and basic oxygen furnace steel production route to the DRI-EAF production route, which results in a significantly lower carbon footprint. The new DRI will be the first of its kind in Spain and the EAF will be in production by the end of 2025.

B

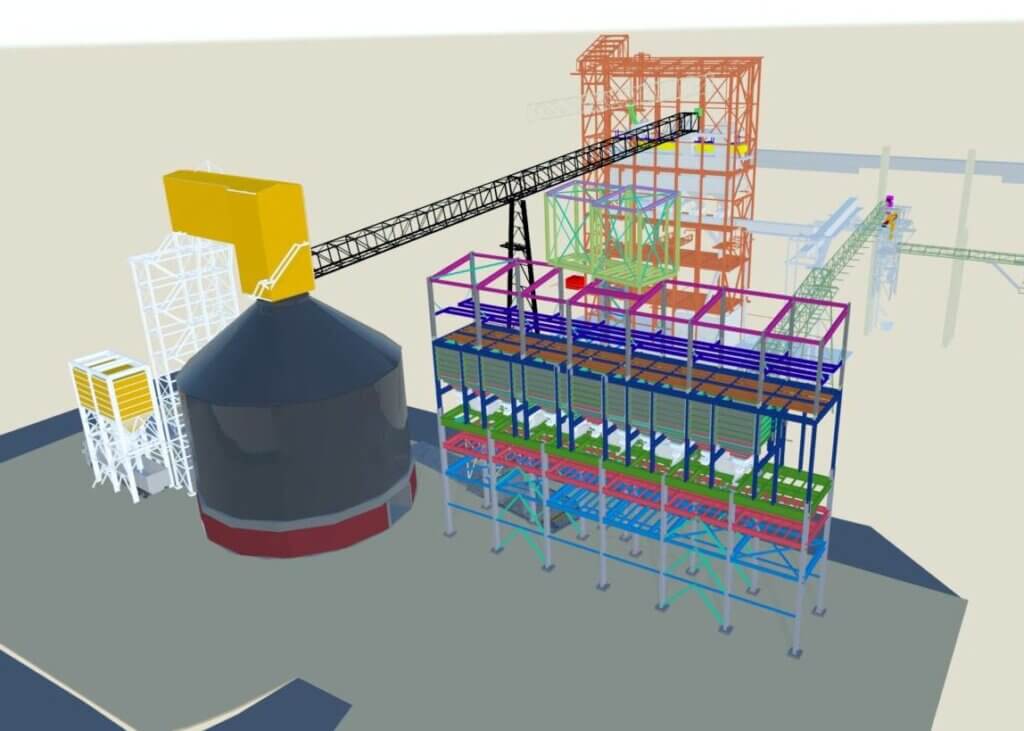

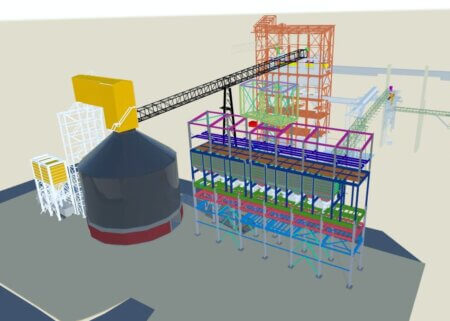

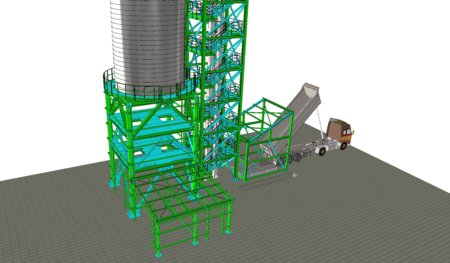

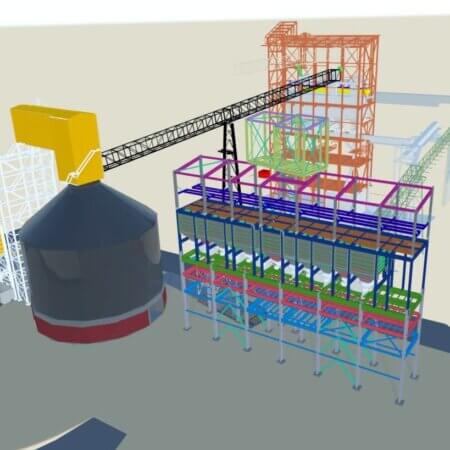

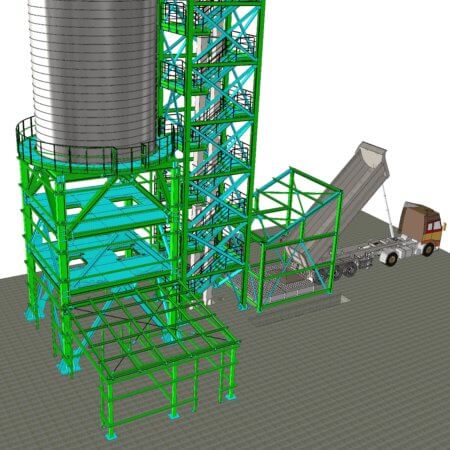

SP has been commissioned for the construction of a 10,000 ton CDRI storage facility at the Arcelor Mittal plant in Gjion , Asturie)!!!.

10.000 TON CDRI SILO

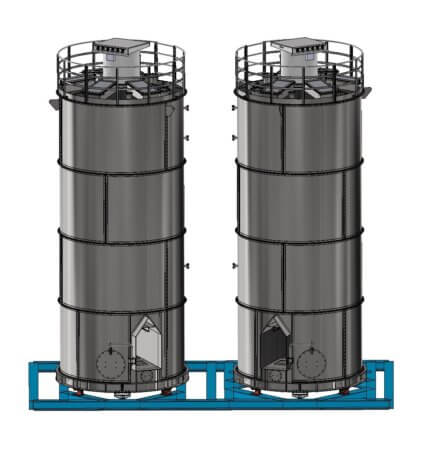

DOUBLE WALLED SPIRAL SILO

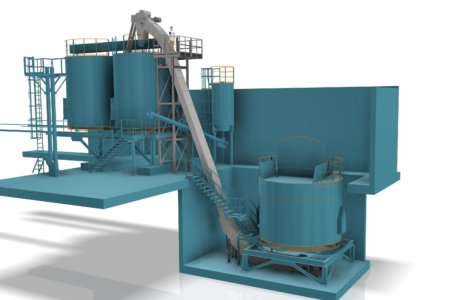

BSP will realized a special type of silo for the storing of the CDRI called “double walled silo”

Flat bottom, 22m diameter – 24m cilinder height, roof 45°angle sloped.

Double wall type consists in a sort of hybrid solution steel/concrete. BSP erect the first cylinder wall through its special double folding system technology that allow the creation of cylinders profiling and folding rolled steel coils directly on site thanks to special automated former machines.

Double wall in galvanised steel sheet coils:

· an outer wall made of metal sheet coils will be erected all around the first wall for a total height of 24.000 mm

· The inner distance between the two walls is 300 mm prox.

· A metal net will be welded to the inner wall between the two walls.

· After anchoring the two walls of the silo to the slab, the inner space between the two walls will

be filled in concrete type top flow.

Double walled design avoids the welding of internal vertical rigid bars, reducing operations on site and speeding up assemblig times.

REALIZATION

COMING SOON….

CONCLUSION

BSP…..